Denim fabric is quite dense, so items made from it last a very long time. But over time, trousers can become worn on the inside of the base of the legs. It’s a shame to throw away your favorite jeans! But we won’t be sad and will show you how you can carefully and quickly save the situation and give your jeans a new life.

Master class: how to mend jeans

1. We have a small hole.

2. Glue a thick serpyanka from the inside.

3. Set the needle thicker (100), loosen the tension of the upper thread, step 2-2.3 mm, so the thread breaks less. We begin to assemble the hole by going about 1 cm into the “living” tissue. We don’t play with the backing for a long time; we sew using reverse stitching.

4. Rarely, but sometimes you have to trim the seam of a connection if a very large hole turns out to be...

5. We make basic darning stitches 2-3 times in different directions, using reverse stitches.

6. When a reliable base has already been stitched, we sew parallel to the hem, turning the jeans under the foot.

The final step is to restore the connecting seam with a denim thread that best matches the color.

Video master class: how to mend jeans

We hope the master class was useful, and your favorite jeans got a second life! Subscribe to our updates, comment and share with friends.

Hand darning- delicate and painstaking work that requires time, patience, and eye strain. A sewing machine will allow you to do darning quickly and efficiently. Of course, we are not talking about artistic darning, which makes the damaged area on good, expensive clothes invisible. It's better to do it manually. Robust and reliable machine darning is good for repairing home, work, and sports clothes, backpacks, tourist tents, as well as bed linen.

Darn you can learn on any sewing machine- old straight stitch, modern multi-operational, manual, foot, electric. To do this, you need to remove the presser foot and lower the teeth of the conveyor, which moves the fabric while sewing.

Prepare the item for repair: cut off the threads sticking out at the edges of the tear, cut out worn out, frayed places. Stretch the area of fabric to be repaired onto the hoop.

Small plastic hoops with a diameter of 15 cm and a height of no more than 8 mm are best suited for this (higher ones are difficult to remove from under the needle). Choose threads to match the fabric.

Set up your sewing machine for a regular straight stitch. The set stitch length does not matter since the feed dog is lowered. Thread tension is the same as for normal sewing. Put hoop under the needle. Lower it into the fabric at the edge of the tear and pull the bottom thread from the shuttle up through the fabric. Even though there is no presser foot, be sure to lower the presser foot lifter to maintain tension on the upper thread.

Now begin, moving the hoop, stitching along the edge of the gap. Please note that when the conveyor teeth are lowered, you can sew the seam not only forward, but also to the side, and at any angle. direction. True, you will have to monitor the uniformity of the stitching yourself. Move the hoop smoothly, without jostling, and try not to bend the needle while it is in the fabric.

A special foot is available for beginner embroiderers and darners. It is included with some machines. Darning foot and embroidery is designed in such a way that its spring presses the fabric when the needle is lowered and releases when the needle is up. Thanks to this, you can work without fear of bending the needle. True, experienced seamstresses do not use such paws, as they believe that this can slow down the work.

But now you have worked the entire circumference of the tear with strong stitches. Now start moving the hoop towards you - away from you straight through the gap in the direction of the grain threads of the material. Do this slowly and evenly. Perhaps this proposal will confuse you: how to sew from scratch? Try it anyway and you will see: the upper and lower threads of the machine, stretching from one edge of the break to the other, form neat intertwined flagella. Try to space them as evenly as possible to fill the entire hole. Once you reach the undamaged edge, stitch along the healthy fabric about 1 cm, and then begin to move the hoop back. Having processed the entire tear in this way, turn the hoop 90° and stitch it in the transverse direction. When repairing thick, stiff fabrics, it is worth making stitches at an angle of 45°, and then turning the hoop again by 90° and darning along the other diagonal.

How to patch with a sewing machine

Darn allows you to repair minor damage. But even with a precisely selected color, machine darning is quite noticeable. The ones made look much neater using a sewing machine patches.

If you have a basic lockstitch machine, this is how you apply the patch. Cut an even rectangle around the damaged area, one of the sides of which should coincide with the direction of the grain of the fabric. Make 0.5 cm cuts at the corners of the rectangle.

Fold the edges of the rectangle inside out to form a frame and baste or pin them. Prepare the flap for the patch. Its dimensions should be several centimeters larger than the cut out rectangle. Fold the edges of the flap over about 0.5 cm. Cut the corners diagonally so that there are no thickenings when folding.

Place the flap on the hole from the wrong side of the product so that the directions of the grain threads coincide. The folded edges of the patch and the hole should remain inside, between the main fabric and the patch. They should not be visible from the front side. Baste the flap.

And lastly, sew two lines on the machine, along the edge of the flap and along the edge of the inner frame, retreating 1 mm from the folds. Now the patch is ready, albeit a little noticeable, but durable, not afraid of repeated washings, equally neat on both the front and back sides.

On a sewing machine, which performs a zigzag stitch, patch even easier and faster. You don't even need to bend their edges. Choose a patch slightly larger than the hole to patch. Place it on the area to be repaired so that the directions of the grain threads coincide, and baste it to the fabric or pin it with pins. Place a zagzag stitch along the contour of the rectangle, stepping back from the edge of the flap by 0.5 - 0.7 cm. Now, stepping back another 1 - 2 cm inwards, perform a similar operation along the contour of the smaller rectangle. Remove the basting or pins. The damaged area was enclosed in a frame of two zigzag stitches. All that remains is to cut out the inner rectangle with the damaged area, and trim the outer edge of the patch along the outer zigzag seam. The seam will not allow the fabric threads to fray during washing and will not create excessive thickness. The stitching should not be too frequent, a step of 2 - 3 mm is enough. The height varies depending on the thickness and texture of the fabric. To avoid thread shedding, at least 5 to 6 weft or weft threads of the fabric should be laid at the stitch height.

Denim fabric is quite dense, which is why things made from it last a very long time. But over time, trousers can become worn on the inside of the base of the legs. This problem is especially common in men or people with full legs.

Sewing jeans between the legs on a sewing machine is quite simple using a machine darning. It allows you to thoroughly strengthen the affected area of a worn product. And since the place of the patch is quite inconspicuous, your favorite trousers can continue to be worn.

To mend jeans worn between your legs with your own hands, you will need:

- sewing machine;

- threads (as close in color as possible to the jeans fabric);

- sharp scissors;

- non-woven fabric (any density).

How to sew frayed jeans between legs using a sewing machine, master class

Before starting work, jeans must be washed thoroughly.

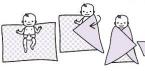

Turn the pants inside out.

Measure the size of the damaged areas. Cut pieces from non-woven fabric that completely cover the holes.

Glue them with a hot iron to the wrong side in the wiped places.

Turn the product right side out. Now you need to completely sew up the worn area with parallel, even seams.

To do this, you need to use a special foot that reverses the stitching.

The seams should be placed along the direction of the fabric threads, parallel to each other and very tightly. So sew up the entire damaged area.

On the wrong side you will get a patch like this. Excess interlining can be trimmed close to the seams.

The more suitable the tone of the thread, the less noticeable the darning will be. If you can't find something perfect, you can use several coils. The combination of colors will make the overall tone a little different.

But in any case, such darning remains unnoticeable, and the item becomes even more wearable.

Hand darning – delicate and painstaking work that requires a lot of time, patience, and eye strain.

Sewing machine Performs darning quickly and efficiently. Of course, we are not talking about artistic darning, which allows you to make a damaged area on good, expensive clothes invisible. Durable and reliable machine darning is good for repairing home, work and camping clothes, backpacks, camping tents, covers, and bed linen.

You can learn to darn on any machine - an old straight-stitch machine, a modern multi-operational one, manual, foot-operated, electric. How to darn on a sewing machine?

To darn on a sewing machine, you need to remove the presser foot and lower the feed teeth that move the fabric while sewing.

Before you start darning, use scissors to trim the edges of the tear: cut off protruding threads, cut out worn out, frayed places. Then stretch the area of fabric to be repaired onto the hoop. Plastic hoops with a diameter of 15 cm and a height of no more than 8 mm are best suited for this (higher ones are difficult to remove from under the needle). Choose threads to match the fabric.

Set up your machine for regular straight stitching. The stitch length does not matter since the feed dog is lowered. Thread tension is the same as for normal sewing. Lower the needle into the material at the edge of the tear and pull the lower thread from the shuttle up through the material. Despite the absence of a presser foot, do not forget to lower its lifting lever, which turns on the plates of the upper thread tension mechanism.

Start the machine in motion and begin, moving the hoop, stitching along the edge of the gap. Please note that now, with the conveyor teeth turned off, you can sew a seam not only forward from you, but also to the side, and at an angle - in any direction. True, you will now have to monitor the uniformity of the stitching yourself. Move the hoop smoothly, without jostling, and try not to bend the needle while it is in the fabric.

A special foot is available for beginner darners and embroiderers. It is designed in such a way that its spring presses the fabric when the needle is lowered and releases when the needle is at the top. Thanks to this, you can work without fear of bending the needle. True, not all cars are equipped with such paws. Experienced seamstresses do not use them - they believe that it slows down their work.

So, you have sewn strong stitches around the entire circumference of the tear. Now start moving the hoop towards you and away from you straight through the gap in the direction of the grains of the material. Do this slowly and evenly. Perhaps this whole operation will confuse you: how can you sew on empty space? Try it anyway, and you will see: the upper and lower threads of the machine, stretching from one edge of the break to the other, form neat intertwined flagella. Try to place them as evenly as possible to fill the entire area of the gap. Once you reach the undamaged edge, stitch along the healthy fabric about 1 cm, and then begin to move the hoop back. Having stitched the entire gap in this way, turn the hoop 90° and stitch it in the transverse direction.

When repairing thick, stiff fabrics, it is worth making stitches at an angle of 45°, and then turning the hoop again by 90° and darning along the other diagonal.

Sometimes your favorite jeans get torn in the most unexpected places. I especially feel sorry for expensive branded jeans, which, it would seem, will not be demolished... And you won’t even raise your hand to throw them away, and you can no longer wear them like that. Sad pictures with awkward patches – wedges from grandma’s times – come into my head... Plans to alter my son’s jeans, take him to the country... and still it’s a pity...

Fortunately, everything can be fixed if you have any sewing machine and you have minimal skills in operating it.

One of the conditions for success is to choose the right threads. Threads are suitable for regular polyester No. 40. The choice in sewing accessories stores is very large. For example, “Ideal” or “Dor tak”. We'll select it like this. Let's choose a suitable color, wind a little bit of thread on your finger, and apply this “winding” to the fabric. The two colors should be almost the same, then the darning will be almost invisible.

We will also need adhesive fabric. It is sold in fabric stores and is quite inexpensive. Comes in white and black.

Now turn the jeans inside out. We cut out pieces of adhesive fabric and apply them to the places where we will do the darning.

We glue our blanks. This will make the darning process easier. The iron must be hot enough. The side with glue is rougher to the touch. Place the patch with the adhesive side on the jeans and slowly iron the pieces, pressing them well. Wait a minute, let it cool and set well.

Darning can be done on any household machine using reverse (reverse motion); even the oldest sewing machines have this function. Set the stitch length regulator to 2.8 -3.0 mm.

We darn slowly at first. Let’s “block” the impulse with a wide zigzag, similar to a cardiogram, moving the line forward and backward. The edges of our “cardiogram” should not be smooth, then the darning will be less noticeable and more natural.

Now we darn very carefully the place of the gust itself and the neighboring areas. If it is inconvenient to darn with large lines, work with small sections, connecting them with smooth transitions. If white threads are knocked out between the lines, point the needle directly at them until they are noticeable. By the way, if the gust is large and there are a lot of threads sticking out, you can trim off the excess, but do not cut off all the threads until there is a complete hole; it is better to leave the base. Although restoration is possible even with the complete absence of threads, it is a little more difficult.

IMPORTANT: the darning will look more natural if you sew in the direction of the pattern, and not in the direction of the hem of the fabric!

Sew carefully, in parallel, without rushing. The result will please you. The skill will gradually appear, and the process will take you no more than 15 minutes. Once the darning is done, turn the jeans inside out and trim off any excess glue.

After the job is completed, the jeans should be steamed using water and cloth. Your diligence will be rewarded. Jeans will last you a long time. It’s especially nice when your family looks at the completed work for a long time and cannot immediately find the darning)