Despite the variety of jeans models, men's jeans The number of pockets often remains the same. According to tradition, there are five of them.

4 regular-sized pockets have a practical purpose: they store small things, money, keys, etc.

The fifth pocket differs from the others in its size; it is smaller than the others. This pocket often causes confusion among jeans owners. Let's try to figure out why they sew a small pocket onto jeans, into which you can't put much.

The history of fashion knows exactly when an unusual pocket appeared on jeans. The age of this detail is approaching one and a half centuries.

The history of fashion knows exactly when an unusual pocket appeared on jeans. The age of this detail is approaching one and a half centuries.

Reference! Customers first saw it on pants in 1873. Entered new tradition Levi's company.

Back in 1873, the company released a new model of its jeans - 501 XX, which differed from others by the presence of a fifth pocket.

The author of this element is considered to be American designer M. Regalo. He came up with a compartment that, according to one version, was intended specifically for storing watches. This is exactly how it was designated in the catalogues: “watch pocket”.

However, initially, jeans owners used it not only for watches. « Golden fever”, which reigned in America at that time, suggested a different purpose. The small, tight compartment was convenient for separate storage of washed-up gold nuggets, and was used for this purpose by many cowboys.

Classic uses for a small pocket on jeans

Gradually, the additional compartment began to be used for other purposes.

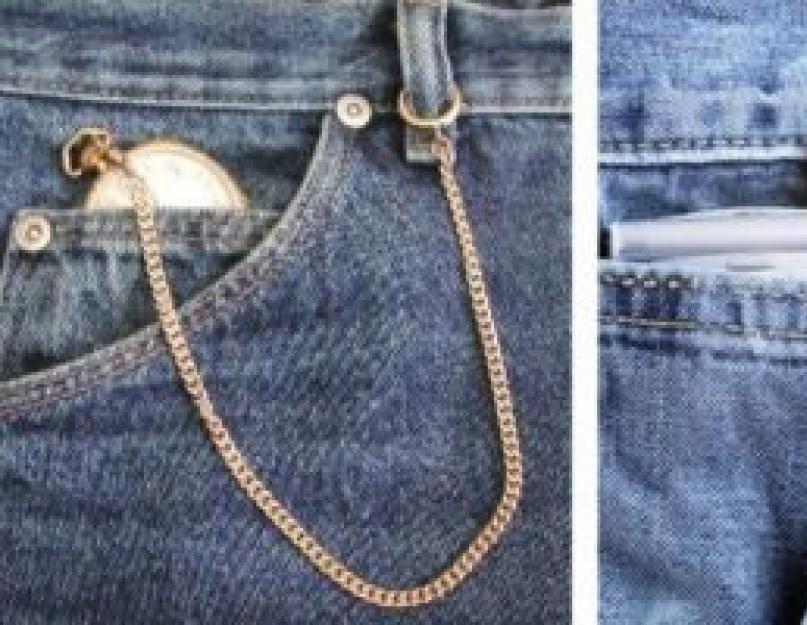

Watch

For a long time it was still used for watches, which in those days were not wristwatches. The watch chain was attached to the belt, and the case lay inside the recess.

For a long time it was still used for watches, which in those days were not wristwatches. The watch chain was attached to the belt, and the case lay inside the recess.

Coins

The pocket turned out to be very convenient for storing small coins. It didn’t take long to look for them among other things.

Small items

This detail was also appreciated by craftsmen who used strong and durable trousers as work clothes. Small parts (small nails, nuts, bolts, washers, etc.) were not lost and were always at hand.

Lighters

Smokers have found another purpose for the small decorative detail. It fit the Zippo lighter perfectly.

Romantic attributes

The lovers used the tiny compartment in their own way. At the right moment, either folded notes of romantic content, or rings indicating the seriousness of intentions, or contraceptives were taken out from there.

The lovers used the tiny compartment in their own way. At the right moment, either folded notes of romantic content, or rings indicating the seriousness of intentions, or contraceptives were taken out from there.

Medicines

There is another version associated with the designer M. Regalo. In accordance with it, it is believed that the author of the idea created a part for storing medicines, and possibly concealing prohibited drugs.

Reference! The fifth pocket in those days was called not only a “watch pocket”, but also a pocket for medicines - a “drugs packet”.

Personal talismans

It was considered important to constantly wear small amulets or talismans, which promised good luck and luck in business. Hidden in a pocket, they were invisible to prying eyes, but instilled confidence in their owner.

Modern use of a small pocket

Changes that occur in life have expanded the purpose of the fifth pocket and led to new options for its use.

Appearance cell phones forced us to look for a suitable place for them. A small denim pocket solved this problem.

It was also convenient to use it to deal with removed sunglasses. They were not inserted, but secured with a bow on the fabric, leaving the glasses on top of the trousers.

Many jeans owners develop individual habits. Some people know that they always have a small knife, others make it a place for chewing gum, others adapted for storing things purchased in transport tickets.

New technologies and the special purpose of the small pocket in Levi’s jeans models

Levi's, the first to add a fifth pocket to its models, is still ahead today. Professionals managed to combine classics and modernity.

Levi's, the first to add a fifth pocket to its models, is still ahead today. Professionals managed to combine classics and modernity.

And now the mini-department has received serious practical application. Buyers noticed that on the new model of Red Wire DLX jeans, the now familiar attribute of jeans looks new. It has a white leather overlay.

But the main difference between the model is the contents of the compartment. The owner of these trousers, along with the clothes, receives built-in headphones, a joystick, and special terminals. Thanks to this, the manufacturer combined clothes with iPOD, and the buyer received maximum convenience in working with it, because you can control the device using a joystick even when the iPOD remains in your pocket.

Important! All devices equipped with the Red Wire DLX model are detachable, making it easy to care for the product.

So a small pocket, which appeared as a decorative detail, became a practical and convenient addition to jeans.

December 15, 2018All information about jeans in one article. Types of denim, fit of jeans, sizes of jeans, brands of jeans, history. The article is great.

What are jeans?

Denim jeans, indigo jeans - today, called jeans (jeans in English), primarily mean men's pants that have the following features:

- Special style.

- Special fabric.

- Special manufacturing technology.

Denim style

These are two patch pockets at the back. These pockets are convenient for putting and taking things out. Two cut-off pockets with an arched-horizontal entrance at the front. This form of entry prevents things from falling out of pockets when sitting.

Straight, loose fit trouser legs that do not restrict movement.

Denim (denim)

Denim, most often called denim (denim in English), is a medium-weight cotton twill of a melange type. According to the English classification, denim belongs to medium-weight fabrics - mid-weight (12 - 16 Oz). Density 12 - 16 ounces per square yard, that's over 400 grams per square meter.

The peculiarity of denim is that ordinary trousers are not made from fabric of such density. But twill of such a high density protects the body very well from dirt, dust and mechanical damage. And it is more durable than traditional trouser fabrics.

Manufacturing technology

Sewing jeans is also different from sewing regular trousers. The peculiarity is that the seams are sewn with double stitching. Closed seams are used.

Metal rivets are used in areas of greatest load.

Metal buttons with rivets are used.

Features of jeans

If you analyze the above features, it becomes clear that jeans are specific trousers designed for use in very unfavorable conditions. For example at work.

This is true. For the first hundred or so years of its existence, jeans were exclusively work wear. And only in the last 60-50 years have they become everyday, fashionable clothing.

Origin of the names jeans and denim

Historians believe that the word jeans is a corruption of the name of the Italian city of Genoa, which came into English from French. In French, Genoa (Gênes) is pronounced Gin. IN English language this word became Zhins, which meant "Genoese". Gradually, the French word Gênes turned into the English word jeans.

What does Genoa have to do with it? The fact is that twill from two-color, blue and white yarn (melange twill) began to be made in Genoa back in the Middle Ages. And since the then Genoese Republic conducted active maritime trade, this fabric was sold in Europe, including England. And it was in good demand because of its low cost and fairly high strength. Thus, over time, the city name of the city of Genoa became the name of the two-color (blue and white) melange twill. And since the second half of the 20th century, this word has been primarily associated with trousers made from melange twill.

Denim. Historians believe that this word was formed in the USA, as a result of “trimming” the name of the French fabric - sergé de Nimes (twill from Nimes). Nimes is a French city that had many weaving factories. Among other fabrics, they made high-density technical cotton twill. For sails and cargo packing. This fabric was also supplied to the USA, where the name denim gradually became attached to it. The first Levi's jeans were also made from this fabric, since in the second half of the 19th century the prices for canvas dropped significantly. It was a cheap and durable fabric - a good material for work clothes.

At that time, denim was made from undyed and unbleached cotton yarn. From the same times came the high density of today's classic denim - from 12 to 14 ounces per square yard. After all, that denim was a technical fabric. At the beginning of the 20th century, denim began to be made from two-color yarn, like twill from Genoa. Denim differs from the old Genoese fabric in its higher density.

The word jeans to refer to blue denim trousers began to be used starting around the 60s of the 20th century. Since this type of workers men's trousers has broken into the casual and fashion segment.

Today, the name denim primarily refers to a medium-weight cotton twill, 12-14 ounces per square yard (400 or more grams per square meter). Twill of this density is considered a classic denim for the production of denim clothing.

In the USA, the word denim, in the plural, is also used to refer to denim pants (jeans). That is, jeans in the USA can be called not only jeans, but also denims. At the same time, the semantic meaning of the name denims does not completely coincide with the meaning of the word jeans. The word jeans refers to pants made from any type of denim fabric. But the word denims means pants only made from classic (true) denim.

The full name of this fabric is melange-type cotton twill (made from two-color yarn). Although denim can be one-color - made from undyed yarn, this type of denim is called ecru; historically, the first denim was just like that.

The peculiarity of twill fabric is that during its manufacture, the warp and weft threads overlap not one to one, but 1 to two or more. The illustration below shows a twill pattern with a 1 to 2 overlap. The warp thread overlaps two weft threads.

Therefore, twill forms a characteristic diagonal thread pattern.

This photo shows a fragment of denim fabric from the front side. The warp threads, dyed in Blue colour. The white thin lines are white (undyed) weft thread. The relief is not visible in the photograph, but the warp threads form diagonal protruding lines on the front side of the fabric.

The diagonal relief of twill is stronger, the denser (heavier) the fabric. In Russian, twill fabric is more often called diagonal.

Twill fabric can be made from different materials(linen, cotton, wool, synthetics). It can be melange (made from yarn of different colors) or single-color. It can be of different densities, including very thin (light).

But the name denim implies absolutely certain type twill. It is a 12 to 14 ounce cotton twill. Moreover, it can be melange or unpainted (ecru). The classic color for melange denim is dark blue, obtained by dyeing yarn with natural or synthetic indigo dye. But today denim is dyed in other colors.

Also, types of twill differ in the ratio of overlap of warp and weft threads. Overlaps are the intersection points of the warp and weft threads. In denim, this ratio is 3 to 1. For one overlap of weft thread, there are three overlaps of warp thread. That is, denim belongs to the category of warp twill (the number of overlaps of the warp thread is higher than for the weft thread).

Types of denim denim

Classic blue denim

Classic denim is a two-tone fabric. The reverse side is light with blue strokes, the front side is blue with light strokes. The heterogeneity of color is due to the fact that the fabric is made from yarn of two colors. The warp threads are dyed blue and the weft threads are undyed (bleached cotton). And since the warp and weft threads are intertwined, they are slightly visible from the opposite side.

To dye yarn in classic denim, natural or synthetic indigo dye is used. Its peculiarity is that it does not penetrate into the cotton fibers, depositing only on their surface. Therefore, under mechanical influence, during use and washing, the dye is gradually “knocked off” from the fibers, and they become light.

This determines one of the iconic features of denim clothing - lightening (up to complete whitening) of those parts of clothing that are subject to the greatest mechanical stress (friction). These are usually the folds of the fabric, the seams, and the front and back sides of the legs.

As a result of prolonged wear, jeans acquire a complex pattern, individual and unique, like the owner’s fingerprints. Denim fanatics specifically rub down their jeans to lighten certain parts. And not just fanatics. Today, more than half of all jeans sold in the world are still finished in factories with grout, but more on this later in this article.

Another characteristic of classic denim, besides indigo dye, is its density. It should be in the range of 12 - 14 ounces per square yard (400 or more grams per square meter). Density is determined by the thickness of the yarn threads, as well as the density of their packing in the fabric.

It is believed that denim, with its unusually high density for clothing, is a historical legacy from the late 19th century, when the first jeans were made from sailing fabric. It was then cheaper than fabric for clothing.

Be that as it may, such a high density has serious advantages. This denim provides good protection bodies from dirt, dust, mechanical damage. In addition, it holds its shape well and is durable under constant use in adverse conditions.

Ecru in French means unbleached. This is fabric from natural materials(cotton, linen), which has not been subjected to any processing. That is, cotton in its original form.

In the historical, denim retrospective, ecru denim is the original denim. The first jeans were made from this at the end of the 19th century. It was only around the beginning of the 20th century that jeans began to be made from blue denim. And ecru left the stage.

However, in the last 20-30 years, ecru denim has made a comeback in the wake of eco-friendly and retro fashions.

Indeed, this is an extremely environmentally friendly fabric, and in the context of denim clothing, it is also an extremely true denim fabric. So today you can find jeans made from ecru denim, but you will have to look, they are not available in any store yet.

The color shades of ecru vary depending on the type of cotton, the quality of the cotton, and the quality of the yarn and linen. But on average it is a light yellow shade, close to beige.

However, ecru denim has a disadvantage compared to indigo denim. This is dirty. More precisely, they have the same soilability, but dirt is visible on ecru much better than on indigo. And this is essential for casual wear. By the way, one of the opinions about why they stopped making ecru jeans is precisely this - indigo jeans can be washed less often, since dirt is less noticeable on them.

There are two options for double dyeing denim:

- Double dyeing of yarn (warp threads). First, the yarn is dyed with one dye, for example yellow, then with another, for example indigo.

- Dyeing finished melange denim. Denim is made in the usual way, with dyed warp threads and undyed weft threads. Then the finished canvas is painted with the same paint.

In the first case, you can get interesting results during finishing. For example, jeans, the yarn of which is first dyed yellow and then indigo. The finished jeans have been finished with grout and look like this:

These are new jeans, but they look like they've been worn for a year and haven't been washed.

The second option, with the coloring of the canvas, is more interesting and common. In classic denim, the front side has a non-uniform color, there are streaks of light color on it. Denim, double-dyed on the canvas, is devoid of this drawback; it has a smooth, deep color. Here are Levi's jeans made of double-dyed denim. On the cuffs of the legs you can see that the back side of the fabric is also dyed. The front side has an even, solid color:

Double painting on the canvas has another effect. As you wear it, a beautiful, contrasting pattern of light lines on a dark background appears on the front side. It looks especially beautiful on black denim.

You can also get a spectacular, contrasting pattern as a result of finishing processing. Here are Levi's Black Tab jeans made of double-dyed denim that have undergone a stone wash finish:

But in real wear, double-dyed black denim jeans give much more beautiful drawing than stone washed.

Selvedge denim

Sevedge is a distorted, over time, expression of self edge (independent edge, edge). The peculiarity of old shuttle-type weaving looms is that the edges of the fabric are fixed without additional operations, due to the weft thread. That is, the canvas comes out of the machine with fixed edges.

Old-style denim was made on shuttle-type looms. Another feature of that old denim was that the fabric was narrow (less than one meter wide).

And these two features made it possible to sew pants without overlocking operations. The parts of the pants were cut in such a way that the edges of the fabric went into the outer seam. And the inner seam was sewn closed.

By the way, this explains why the classic cut of Levi's jeans is exactly like this - a closed seam on the inside. Although today this is no longer necessary, because they have long been using wide fabric and the details of the pants are overlocked. But nevertheless, Levi's still makes a closed seam on the inside today. This is also where the classic denim stright style comes from, a straight cut on the outer sides of the legs.

It is economically unprofitable to produce such a narrow, dense fabric, compared to a wide fabric on shuttleless looms. And today it is made in very small quantities. This is a niche product aimed at denim fanatics. Today selvedge denim is made in the USA, Japan, Italy, Portugal and some other countries. In the USA and Japan it is made on the original old looms (which were produced in the first half of the 20th century).

The most notorious denim fanatics are the Japanese. They not only make salvage denim on old machines, but also sew jeans from it using old patterns, on old equipment.

The edges of the fabric are regular denim and selvedge denim:

Selvedge denim in ready-made jeans, you can see that the edge of the fabric is in the outer seam:

The width of salvage denim does not allow for efficient cutting charts for very small and very large denim sizes. And the cost of the fabric itself is higher, due to the low productivity of shuttle looms. So, today the entire denim mainstream is made from modern wide denim.

If we talk about the quality of the fabric, salvage denim does not have any advantages over denim, which is made on modern equipment. On the contrary, modern equipment makes it possible to obtain fabric of higher quality and at a lower cost.

Sanforized denim

Sanforization of denim is a technology for processing the finished fabric (after the weaving machine). The purpose of this treatment is to reduce shrinkage of the fabric during further washing of finished products. The canvas is soaked with water or steam and then pulled between compression rollers. After this, the fabric is dried. This treatment helps reduce fabric shrinkage during washing.

For denim, shrinkage during the first washes can be 10% of the original size. Denim shrinks especially strongly along the length of the fabric. After sanforization, future shrinkage of denim can be reduced to 1-2%.

Raw denim (raw, rigid denim)

Raw denim is denim that has not been washed. Washing treatment is done for the following purposes:

- Completely “shrink” the denim.

- Make denim color brighter and more saturated.

- Make denim soft.

- Wash off the most unstable part of the indigo dye.

Raw denim (rigid denim) is a stiff fabric and the color of the front side is not very beautiful - dull dark blue with gray tint. But after intensive factory washing, the fabric becomes soft and acquires a bright dark blue color.

Also, raw denim (rigid demin) is also a dirty fabric. As was already written above in this article, indigo dye adheres only to the surface of the fabric fibers and “knocks off” from it upon mechanical contact with other surfaces (things, furniture, body). There is a lot of dye on freshly made fabric and therefore classic denim in its factory state is stained. The indigo dye remains on all surfaces the material comes into contact with. And this continues until the jeans are washed at least 3-4 times.

Washing treatment can be done not only on canvas, but also on finished products. And most often, washing treatment is done on finished products. One of the tasks of finishing finished jeans is washing off the most unstable part of the indigo dye.

Sanforizing denim is not considered washing. Washing treatment can have different intensity. From the weakest rinse wash before radical washing acid wash And light wash. The canvas is usually processed no more than rinse wash. More strong washes are already performed on finished products.

When buying jeans made from rigid denim, you need to keep in mind that after the first washes they will shrink in size. The amount of such shrinkage depends on whether the fabric has been sanforized or not.

There are two types of twill, according to the direction of displacement of the warp threads - right-handed (z twill or right hand twill) and left-handed (s twil or left hand twill). Historically, right-handed twill was the first; later, the Lee company came up with left-handed twill. There is an opinion that left-handed denim is softer and more tactilely pleasant than right-handed denim.

In right-handed twill (z twill), the warp threads are shifted to the right and on the finished fabric the diagonals go from bottom left to top right. In left-hand twill (s twil), the warp threads are shifted to the left. And on the finished fabric the diagonals go from bottom right to top left.

But both of these types of denim have a problem. If the fabric has not been sanforized, then, after washing, the legs of the jeans curl up. And it can be so strong that the seams, at the very bottom of the pant leg, can even appear in front and back.

In search of a solution to this problem, Wrangler, in the early 1960s, decided to use a type of twill weave called herringbone, which had previously been used in the manufacture of heavy wool twill known as tweed. When making tweed, the warp thread changes direction from right to left and vice versa.

The Blue Bell company (manufacturer of the Wrangler brand) gave a new type of denim the name “broren twill denim”. The first model of jeans made from broren twill denim was the Wrangler 13MWZ jeans.

Some Internet sources write that Blue Bell invented broken twill, but this is not so. This type of twill weaving has been known for a long time and is used in various twill fabrics. The Blue Bel company came up with only one thing - to use this weaving to produce denim. So the exact name of the Wrangler fabric is broren twill denim.

The photo shows jeans made from broren twill denim. The thread pattern is better visible from the wrong side of the fabric:

Broren twill denim on the right and left-handed denim (left):

Chambray denim

You can find articles on the Internet that say something like “chambray is a thin denim fabric.” Or even that chambray is thin denim. Like denim for shirts, etc. products.

But it's not right. Chambray fabric is similar to denim only in that it is a melange fabric (made of two-color yarn). They also use undyed yarn for the weft threads. But chambray is not twill, it is a fabric from the group of so-called “flat” (plain) fabrics (plain weaving of threads). When making chambray, the warp and weft threads are intertwined without displacement, at right angles.

Thus, chambray is not denim, but a melange fabric.

Stretch denim

Stretch is a twill that, in addition to cotton, also uses synthetic fibers. Typically, in the manufacture of stretch denim, 1-3% of synthetic elastane fibers are used (aka spandex, aka lycra).

Adding synthetics allows denim to stretch. This denim is used for fashionable denim cuts (fits) slim and skinny. These are types of cutting blanks, the finished products from which “sit tight” on the body. It is difficult to make such models from classic denim; you have to create complex cutting patterns. And if the fabric stretches, it is much easier to make skinny jeans from such fabric.

Levi's avoided using stretch denim for the longest time. But in 2016, they also began making versions of the 501 model from stretch denim.

There is no consensus on whether stretch denim is better than regular denim or worse. In any case, stretch makes it possible to reduce the cost of producing fashionable tight-fitting denim, where it makes sense. However, the use of stretch is questionable when sewing regular jeans, classic fits, such as Levi's 501. Or when sewing relaxed and loose fits, which are very popular in the USA.

Ideologically, perhaps this is not quite real denim. But at least it's very close.

From a health point of view, there is nothing wrong with 1-3% synthetics. However, you need to know that in China (and not only there) under the guise of stretch denim they make fabrics in which the synthetic content can be tens of percent, and even mixtures of different types synthetics. And this is no longer denim.

Denim colors

Denim available today different shades of blue color. From canonical dark blue to light blue. How are these fabric colors obtained? The intensity of the blue color in denim depends on the number of yarn dyeing cycles. One dyeing cycle involves dyeing the yarn and drying it after dyeing. To obtain a dark blue color, the yarn goes through up to 10 dyeing cycles. As the cycles decrease, lighter shades of blue are obtained.

In the Soviet Union, denim was made in at least one enterprise, the Krasnodar Cotton Mill. In the 80s, I saw this denim with my own eyes and held it in my hands. At that time I already had real american jeans(Lee and Levi's), so I could compare. Unfortunately, I did not inquire about its technical characteristics then. But subjectively, according to personal feelings, it was thinner than the American one. Perhaps its density was around 11-12 ounces.

Interestingly, this fabric did not cause any excitement among any of the plant workers. Well, we’re making jeans, so what’s wrong with that? I don’t remember seeing any of the plant workers wearing clothes made from this denim. Although many people made clothes from other fabrics of the plant. Maybe it was because denim clothing was then of little interest to anyone in the Soviet provinces?

At the very end of the 80s and the beginning of the 90s, boiled jeans were made from this Krasnodar denim in the Baltics. At that time there was a surge in fashion for such clothes.

And today, on the site of that plant shopping mall. And in that huge workshop where they made denim, they are now selling imported sad shit.

Italian denim

In my opinion, Italian denim is at least one of the best in the world. I had several Italian jeans made from Italian denim. There is still one pair. Very good color, normal density, sheds well, the fabric is soft and pleasant. If I were making jeans, I would use Italian denim. In Italy today they mostly make modern, wide denim. But they also make salvage denim. Although of course in small quantities.

Denim fit, fit

The English term clothes fit has the following meaning - cutting out the details of clothing. Any clothing consists of individual parts, pieces of fabric. When these parts are sewn together, the result is clothing.

The shape of the clothing depends on the shape of the parts. The cut of the parts determines how the finished garment will look (fit) on a person.

More generally, fit is the overall silhouette of ready-made clothing.

Regular Fit jeans

This type of cut (fit, fit) of jeans is the most common today. The most famous model of jeans that uses this fit is Levi's 501. Wrangler has an almost identical model today, this is the Texas model, it differs only in that the seam is on the outside. And in general, this fit, regular fit, is available on all jeans manufacturers.

It began to be used after jeans went beyond the boundaries of work wear and became casual and fashionable clothing.

This is a cutting option in which the finished jeans should be quite narrow at the hips, but not tight and especially not tight. Of course, you can see people on whom Levi's 501 or Wrangler Texas fit like a second skin, but this is simply the wrong size - the person wears a smaller size than necessary for his figure.

The peculiarity of the regular fit is that the legs taper from the knee to the bottom. If the leg circumference at the knee is, for example, 17 inches, then at the bottom of the leg it will be 16 inches. This is due to the fact that trouser legs that are tapered towards the bottom look better than straight ones, as they were made in the first half of the 20th century.

For size 32 inches (circumference in the waistband of jeans), the numbers are exactly the same - 17 inches at the knee and 16 inches at the bottom of the leg. By the way, in American stores, the specifications of jeans often indicate the coverage at the bottom of the leg, for this in America there is a separate measuring term - leg opening.

The disadvantage of this fit is that it is not well suited for cold weather when you need to wear warm shoes. The narrow leg does not fit well over winter boots, often bunching up and exposing the leg. If we talk about boots, then a regular fit trouser leg cannot be pulled on just any boots.

But with summer, spring and autumn shoes Regular fit is ok to wear. These jeans can also be tucked into boots, which by the way is very popular in the USA.

Regular Fit boot cut, boot jeans

Historically, the first and simplest cut of denim pants. The most famous jeans model that previously used a boot cut fit is Levi's 501, which was made until the mid-20th century.

It is often called simply boot cut. In general, the same as regular fit, but the leg from the knee does not taper, but remains the same width. Sometimes it can be a little wider. Rarely, they produce models with a very strong expansion of the trouser leg towards the bottom.

Another option for the boot cut is to narrow the trouser leg at the knee and then widen it towards the bottom. This gives a stronger visual flare effect.

But the most common boot cut option is the pant leg straight from the knee. If the circumference at the knee is 17 inches, then the bottom of the leg will also be 17 inches. This fit is often called straight fit or straight cut.

The peculiarity of this fit is that the trouser leg fits well over heavy shoes. Boots, as well as winter and work boots. When the trouser leg is placed over a boot or boot, it prevents dust, splashes of water, snow, etc. from getting into the shoes.

For our country, this is perhaps the most practical denim fit. Considering the fact that in most of the country we wear boots for more than half the year.

Also, this fit may be better suited for people with large size legs (larger than standard). On such a person, regular fit may not look great at all.

Strictly speaking, this is not a fit in the full sense, but a design option for a trouser leg from the knee to the end. In English terminology this is called cut. However, in many stores this stands out as a separate fit.

Straight leg, straight jeans fit

Ambiguous name. In some stores and some manufacturers, this fit includes models not only with a straight leg (boot cut), but also with a tapered leg, as in a regular fit. So you need to be careful when purchasing such a fit. Apparently this fit simply means a straight outer seam.

Relaxed Fit jeans

Relaxed Fit is a very popular fit in the USA. Its peculiarity is that the leg is wider at the hip than in the regular fit. As a result, these jeans fit very loosely and do not restrict movement at all.

In this fit, for a person with a standard hip size, jeans should only be held at the waist. Alternatively, this fit can be used by people whose hips are larger than standard and who have a regular fit that fits snugly.

Anyone who wore Levi's 501 strictly according to their size knows how uncomfortable it is to sit or actively move in them.

Loose fit jeans

An even looser fit than the relaxed fit. Depending on the manufacturer, this can range from a very loose to baggy fit. In this fit, for a person with a standard hip size, jeans should only be held at the waist and hang freely along the rest of the length.

Tappered leg, Tappered cut

This is not a fit, but, like a boot cut, a cut option for the very bottom of the trouser leg. The opposite of the bootcut, that is, the bottom of the leg opening is narrower than in the regular fit. This version of the bottom leg cut can be used with regular and relaxed fits.

Slim jeans fit, Skinny jeans fit

Fashionable modern plantings. Especially popular with women. Slim fit means tight jeans, skinny fit means tight jeans (like a second skin). These jeans are made from thinner fabric and most often from stretch denim (with the addition of elastane).

Boyfriend jeans fit (boyfriend jeans)

Analogous to fit relaxed, but for women's jeans. What does boyfriend have to do with it? According to marketers, such jeans should look as if they were men's jeans, which the girl took from her boyfriend. Like the way girls dress Men's shirts instead of your home clothes.

In reality, of course, this is a marketing ploy to sell more jeans to women. But true boyfriend jeans are jeans that a girl wrested from her boyfriend. And what is sold in stores under this name is an imitation, a fake.

It is believed that the first widely known case of a woman wearing men's jeans was American actress Norma Jeane Mortenson in the film "The Misfits".

Although, of course, by that time women had been wearing men's jeans for a long time. Simply because there were no others. After all, only in the late forties of the 20th century, under the Lee and Wrangler labels, the first models of women's jeans appeared.

Mom jeans

This is not a fit, but a humorous expression popular in the USA. Something of a synonym for outdated, unfashionable jeans. Most often, mom jeans refer to high-rise jeans.

Jeans waist height - high, medium, low rise jeans

Rise - just like cut, this is not a fit, but part of a fit. This is a design option for the top of the jeans, from the crotch to the waistband.

High rise- a jeans belt around a person’s waist. In the photo are Levi's high rise jeans:

Medium rise- the waistband of jeans is slightly lower than a person’s waist. One example of medium rise is the modern Levi's 501 model.

Low rise- the waistband of jeans is almost on the hips. The photo shows Low rise boot cut jeans:

Plantings (fits) in pictures

Graphic representation of denim fits:

Jeans manufacturers

Today, all over the world, there are probably tens of thousands of large and very small companies that produce jeans. Many of them do not do anything at all themselves, but simply order production from specialized sewing factories. But more than half of the global denim market belongs to three American brands.

Levi Strauss and Company - Levi's jeans

Historically the first jeans manufacturer. And the only one of the big three who remained an independent company. The first production was in San Francisco. Today it is the company's headquarters. Since the beginning of the 2000s, Levi's no longer makes jeans on its own; the company places orders from other (clothing) companies. And it closed its last factories at the very beginning of the 2000s. Now, almost all, and possibly the entire volume of Levi's jeans are sewn for outside the USA. In any case, in the American online store Levi's, in 2018, there are no models marked “Made in USA”, there are only “Imported” or “crafted in USA”, that is, made in other countries.

The Levi's company divides the production of jeans on a regional basis. For example, those jeans that are sold in the USA are sewn in Mexico, Costa Rica, Colombia, Haiti, Pakistan, Bangladesh. And those jeans that are sold in Europe (including Russia ), mainly sewn in Turkey, Poland, Hungary, Spain, Italy. Not only tailoring, but also denim production is divided into countries. Levi's jeans are made from Turkish denim in Turkey and Poland.

In general, the list of contract manufacturers who do something for Levi's is very large. From this list you can study geography. For example, do you know that there is such a country as Lesotho? I don’t remember where it is. And Levi’s are made there. This list can be viewed on the Levi's corporate website. This list is updated regularly and today it is a sheet of several pages of neat text.

Wrangler (Blue Bell) - Wrangler jeans

At the beginning of the 20th century, it was formed as a workwear company called Blue Bell. The company contributed to the development of denim clothing, in particular they came up with broken twill denim. Wrangler is a trademark of the Blue Bell company; under this brand the company has been producing jeans for cowboys since the forties of the 20th century. For example famous model The Wrangler 13MWZ is a cowboy style jean made from 13 oz broken twill denim.

Since 1986, Blue Bell has been owned by VF Corporation and today it is simply a trademark. Although quite authentic jeans models are produced.

Just like Levi's, VF Corporation orders the production of jeans under the Wrangler label on a regional basis. For example, European Wranglers are made in Tunisia, Pakistan, Turkey, Mauritius. And those sold in the USA are produced mainly in Mexico.

Lee jeans

In the late 19th century, it was formed as a workwear company called the Lee Mercantile Company. The company contributed to the development of denim clothing, in particular they came up with left-hand denim (left hand twill).

Since 1969 it has been owned by VF Corporation and today it is simply a trademark. Although quite authentic jeans models are produced.

Just like Levi's, VF Corporation orders the production of jeans under the Lee label on a regional basis. For example, European Wranglers are made in India. And those sold in the USA are produced mainly in Mexico.

Big denim three piece

All three big denim brands are no longer made in-house. This is contract manufacturing from third party manufacturers. So now these labels are, in fact, ordinary jeans. This is how Turkish Levi's or Wrangler differ from Turkish Colin's or Mavi? Yes, nothing except labels and small parts design and processing.

As you can see, today the most “American” jeans are made in Mexico. Nevertheless, label owners try to maintain at least some authenticity of their products. In any case, the quality of products under these brands is guaranteed at a fairly high level. Regardless of where and who sews these jeans.

But in Russia, in my opinion, the prices for the originals of these three labels are clearly overpriced. If in the USA they cost on average around $50 (the most popular models), then in our country the same models cost around $100. Turkish or Polish jeans for $100? For what?

As for me, now it makes sense to buy any of these three labels only online and only on sale somewhere in Europe or the USA. Buy for $30, plus $20-30 shipping. Under such conditions, you can still take it. And for a hundred dollars it’s better to buy jeans made in Russia from good denim. Or Italian. Or Turkish for 50 dollars.

Jeans sizes

Jeans made in USA (USA jeans)

If you buy jeans in American online stores that are focused on the domestic market, this does not mean that they will contain goods made in the USA. Please read product descriptions carefully. If you see the word Imported there, it means the item was made outside of the United States. Even if it is an American brand product.

If the product is truly made in the USA, this will definitely be mentioned in the product description. Made in USA label means that the product is made in the USA from American materials. It may be marked “crafted in USA” - this means that only part of the work was done in the USA.

Levi's has a Vintage series, which are made as copies of jeans from the mid-20th century. Some of these models are made even abroad (probably in Mexico), but at least from denim produced in the USA (Cone Mills is a historical supplier of denim for Levi's). In the American Levi's online store, the description of such models indicates the origin of the denim if it is made in the USA. But in general, there are no 100% made in USA jeans in the American Levi's online store today. Although there were such models in the 2000s, they then cost about $200. Today, even vintage models for $240 and those are Imported.

Wrangler has made in USA models. In their American online store, there is a separate section of the catalog, which is called - made in USA.

In addition, there are small and small companies that specialize in this segment - made in the USA. There are also companies that make work clothes and usually have several models of jeans in their product range. Here it is necessary to note the difference between the United States and other countries in the context of denim clothing. In the USA, jeans are still considered work clothes. That's why classic models jeans (without the bells and whistles) are available in the assortment of many American companies producing work clothes. However, not all such companies make their products in the USA.

Some companies that make jeans in the USA:

Denim Express- American online store (for the US domestic market). They have their own label, Denim Express, under which they sell several styles of jeans made in the USA. They have a special made in USA section on their website.

Round House- American company, an old manufacturer of work clothes. The company operates in the US domestic market. Their product range includes jeans in classic styles. Such models are marked in their catalog as “made in USA”.

Diamond Gusset- an American company, a manufacturer of workwear and denim clothing since the 80s of the 20th century. The company operates in the US domestic market. In their catalog they have men's and women's jeans of all fits that are popular in the USA. They specifically have a model of motorcycle jeans that is reinforced with Kevlar fabric. They also use a gusset on the crotch seam in some of their jeans. Which reduces the famous problem of jeans - fraying of the fabric in the crotch.

In general, if you wish, today you can find and buy jeans made in the USA. However, this will most likely have to be done through an intermediary company, since companies focused on the domestic US market do not ship outside the US. But this is not a problem, since there are intermediary companies that forward orders from the USA to Russia.

The funny thing is that even taking into account the cost of shipping from the USA, jeans made in the USA can be comparable in price to Turkish or Polish Levi's, which are officially sold in Russia. For example, all three companies listed above have jeans models that cost significantly below 100 dollars. While in Russia 100 dollars is the average price for budget models of large American brands.

Jeans made in Russia

Of course, jeans are also made in Russia.

Gloria Jeans, Gloria Jeans

Our most famous manufacturer. Sewing production is located in the Rostov region. Produces denim clothing under trademarks Gloria Jeans And Gee Jay. In the 2000s I bought Gloria Jeans gray. They faded well and correctly, the cut (fit) was normal, classic. The fittings are good. But denim is not a fountain.

Firstly, it was thinner than Levi's or Wrangler (not even American-made), according to subjective feelings, somewhere around 11-12 ounces. Secondly, it was loose (after washing). And thirdly, it was smaller more durable than Levi's or Wrangler - that pair of Gloria Jeans wore out pretty quickly. However, I rate them overall as good. You can buy these jeans. Perhaps I’ll even buy myself some Gloria Jeans. Considering their price, this is a very good option.

The only large (industrial) jeans manufacturer in Russia. I would say that Gloria Jeans for Russia is like Levi's for the USA. Outside of the USA, Levi's is prestigious expensive clothing, but in the USA itself these are budget, ordinary pants that can be bought everywhere, even in supermarkets.

And this is not my personal opinion. If you look at the analysis of search queries in Russia, there are dozens of search phrases related to Gloria jeans. Mostly, of course, people are looking for the nearest store of this company. So this is really Russian Levi's.

But today they probably make most of their products in Asia. Although I don't know this for sure.

Plan B jeans- a small Moscow company. They sew in Russia, but use salvedge denim from Italy and Japan. The assortment is small, the general style is true denim for connoisseurs. Prices are mostly comparable to Turkish-Polish Levi's or Wrangler. I think the quality of their products is high, but I personally have not worn them.

RussJeans- a small company from St. Petersburg. They sew in Russia, but use denim from Italy and Japan. Prices are lower than for Turkish-Polish Levi's or Wrangler. The assortment is small, there is only one style - the classic Regular. The photos show normal jeans, but I personally haven’t worn them.

Miracle Jeans (Miracle Apparel)- a tiny company from Omsk. Only two models, both slim fit.

Grunge John Orchestra. Explosion (GJO.E)- Moscow company, makes outerwear. The materials are imported and sewn in Russia. There are several models of jeans made from Japanese salvage denim. Prices are significantly higher than for Turkish-Polish Levi's and Wrangler.

MoroZoni- a small factory in Armavir. Judging by the photo, they make jeans with interesting designs. But where to buy them is the question. They don't have an online store. I couldn’t even find the company’s website.

Urbano is a clothing factory in Krasnodar. In the 2000s and early 1900s, it was one of the best (in terms of quality) manufacturers in Russia. But it seems that now they no longer work. In any case, their website is dead.

Kuban Jeans (trademark Ligas)- garment factory in Krasnodar. They make denim clothes mainly for children. Like Gloria jeans, they make products for the budget segment. For adults, one or two styles of jeans.

http://www.kjeans.ru/- a small Moscow clothing company. They had their own denim brand, Excite. But in December 2018, their website stopped opening.

Finishing jeans

The difference between denim clothing is that it is more valuable when worn. When the paint fades, scuff marks appear. Why this happened is not known for certain. Maybe because in many Hollywood films the characters are dressed in worn jeans. Or maybe because worn jeans are more beautiful than new ones.

Anyone who has seen jeans in the so-called rigid or raw form, that is, made from factory denim, knows that they look unattractive. Moreover, they are not particularly pleasant to the touch. Rigid fabric, some dirty blue color. And it’s a completely different matter after several months of wear and 5-10 washes. The color turns bright blue, the fabric is soft, small light abrasions appear, which look beautiful against the blue background.

Whatever the reason, the vast majority of jeans sold today are finished products. Such processing can vary in intensity and technique, but the essence is always the same - to give new, factory-made jeans a worn look. Industrial finishing of jeans began for the first time in the 80s of the last century. Before this, the owners of jeans themselves did this, not all of them, of course, but those who did not want to wait for the jeans to age themselves.

The finishing treatment of jeans varies in intensity. From the weakest rinsed until partial tissue rupture ( ripped).

Rinse jeans, rinsed jeans

Easy wash. The goal of this treatment is to remove the most unstable part of the dye from the fabric so that the jeans are less likely to stain everything they touch. And also make the fabric a little softer.

Stone washing, stonewashed jeans

The most common way to process jeans. Special round stones and finished jeans are loaded into special drums. During rotation, the stones knead the fabric. This type of treatment varies in intensity - from weak ( dark stonewash) to strong ( light stonewash). After this treatment, the jeans become completely soft, and some of the dye is also removed. This type of treatment produces a characteristic slightly mottled surface. Small light abrasions appear on the front side of the fabric. Weak ( dark) stonewash can be very beautiful. Levi's and Wrangler know how to do it beautifully.

Artificial rubbing of the surface of jeans, which simulates abrasions during wear. The simplest and most common type of fading is rubbing the front and back sides of the legs.

There are also more radical forms of fading, for example the creation and subsequent rubbing of creases on the fabric:

Faux fades can be beautiful. But much more often he is ugly and even terrible.

Artificial fading has disadvantages:

- Similarity of jeans. Even if the fading is done efficiently and beautifully, it is still the same type of pattern for a whole batch of jeans.

- Artificial fading can ruin your own, natural fading, which will gradually appear during wear. They will overlap each other and you will end up with an unattractive mess.

- Artificial fading destroys the fabric of jeans. And as a result, their wear life is reduced. That is, when buying new (faded) jeans, you are buying pants with worn-out fabric, which will quickly tear in the faded areas.

Processing finished jeans with pumice stones in a chlorine solution. As a result, very light, even white, spots appear on the fabric. In low-cost production, various bleaching chemicals can be used instead of this technology. As a result of this treatment, cotton fibers lose their elasticity and the fabric becomes brittle. This can be especially noticeable on folds (creases) of the fabric.

Distressed jeans, ripped jeans

Artificial physical destruction of fabric, which simulates severe, extreme wear of jeans. As a rule, this type of treatment is used after other treatments - fading or acid washing.

Low rise boot cut jeans, double treated - fading And distressing:

High rise jeans, double treated - acid wash And distressing:

For the most part, jeans that have undergone radical finishing do not look great at all, and often even look terrible. The worst finishing treatment is found on cheap jeans from Asian countries. But in addition to appearance, there is a practical factor: the stronger the finishing treatment, the faster the jeans will “die.” During finishing, jeans are etched with chemicals, rubbed with grinding machines and sandblasters.

And we get stories like this: a person buys seemingly new jeans, but they “fall apart” after a few months of wear. And he complains to everyone that jeans (label name) are crap. And the only reason is that he bought jeans that had undergone a fierce finishing process.

Personally I think that The best way finishing this dark stonewash. Advantages:

- The fabric no longer smears paint all around it.

- The fabric is already soft.

- Bright, deep color.

- Durable because the fabric is very lightly damaged.

- There is a supply of dye for pronounced natural fading.

But if you have time and desire, you can buy rinsed or even rigid jeans and wash them yourself 7-10 times, at very short intervals. This will improve the color and they will stop staining with paint. And after that they can be worn as usual. What you need to know when washing yourself:

- Do not make the water temperature more than 30%.

- If you machine wash, turn your jeans inside out before washing.

- If machine washable, use the gentle wash and spin method.

The fabric itself will withstand any washing cycle, but the paint will not. With intensive washing, unsightly abrasions may appear. And the best way is handwash in the bath, using a clothes brush on straightened jeans.

Summary

Of course, a lot more can be written about jeans. For example, in this article I did not mention Italian jeans at all. And they deserve it. Perhaps even to a greater extent than modern Levi's. I wrote above that in Russia, there are a lot of requests for Gloria jeans. And what brand is in second place in terms of the number of search requests? These are Italian Armani jeans. I had Armani jeans, a few years ago, the model is almost a replica of Levi's 501, but the workmanship is noticeably higher. And the denim is better (Italian), the production is also better, the finishing is better.

Which jeans to buy today? I already wrote about the big denim three-piece above. You can buy if you can get it for no more than $50. For 100 or more - I don’t see the point. For that kind of money you can buy better jeans.

And jeans are no worse than modern Levi's, in Russia you can buy for less money. Some Turkish label (Mavi, Ostin and others). Or Japanese Uniqlo. Or something inexpensive Italian. Or Swedish cheap monday, which are sewn in Italy. Or those Russian companies, about which I wrote above. The choice is large.

If you want to buy real American jeans, look for small American companies that make work clothes. These will be American jeans not only in terms of where they were made, but also in spirit, in their original essence.

Fake Levi's jeans.

Model 501 is especially often counterfeited. And this is understandable, because this is the most famous model of jeans in the whole world. In fact, there is nothing wrong with them. The main thing is not the fact of a fake, but the quality of it. In the 90s, I bought myself a pair of Turkish fake Levi's 501. In terms of fabric, cut and quality of tailoring, they were no worse than the original ones of that time. The differences were only in the little things - buttons, rivets, labels, some seams. They served me well as good as the real ones. And they cost a third of the real ones.

How to determine the density of denim in finished jeans?

If there is no practical experience, then approximately the density of denim can be determined by the weight of the jeans. In many stores, the characteristics of jeans are indicated for sizes 32 - 32, this is considered the average size for jeans. Such jeans should weigh from about 700 grams. If they are made from 13-14 ounce denim. For example, Levi's and Wrangler regular fit jeans in sizes 32-34, made from the right denim, weigh about 800 grams.

If the jeans size is larger, say 33 or 34 (in the waistband), then the weight should be more than 800 grams. The type of fit also affects the weight of jeans - a relaxed fit will weigh more than a regular fit. If jeans in size 32 - 32 weigh 600 grams or less, this clearly indicates thin denim.

Thin denim may be one of the signs of fake jeans famous brands. But not always. For example, in the modern Levi's 501 model, the density of denim ranges from 11.5 to 14 ounces, depending on the country of manufacture. And in this case, thin denim 11.5 ounces will not be a sign of fake Levi's 501. In general, the modern Levi's 501 model is a real zoo according to characteristics and manufacturing details.

What are (true jeans) true jeans?

The question is almost philosophical. Denimheads fanatics believe that these should be rigid pants made from selvedge denim. Moreover, denim must certainly be woven on old looms. But this topic somehow does not cover the issues of cotton and yarn. What type of cotton should it be? Should this cotton be harvested using old machinery? What kind of carding and spinning machines should there be? Many questions. Something tells me that modern selvedge denim is not particularly true.

And I think that true jeans are those that correspond to the history and spirit of this type of clothing. Cheap, unpretentious clothes that you wouldn't mind killing. Clothes you don't think about. If necessary, go to the nearest store and buy it. If it got dirty or torn, throw it away and buy a new one. And in this sense, it seems to me that in Russia Gloria Jeans is more true than Levi's or Pure Blue Japan.

Homo Simplex, 2018

Everyone knows what it is tiny pocket on jeans, but few people thought why it might be needed. Interestingly, it was originally a place to store watches. So why do jeans have a small pocket?

On one of the forums, when discussing this topic, it was stated that in the 1800s, cowboys used a watch pocket. A representative of one of the most famous jeans manufacturers - Levi Strauss - confirmed this in his blog. And while most of us don't put a watch in our jeans, that doesn't mean the pocket becomes useless.

Levi Strauss allows: it can perform various functions, including a container for condoms or coins, matches or tickets.

Why do jeans have a small pocket: another theory

This pocket was originally designed to hold a Zippo lighter. Its original size was exactly this. That is, not very deep and wide enough for her. Since most cowboys used Zippo, Levis decided to adjust the dimensions of this pocket to one standard.

Now everything has changed, and jeans are made taking into account other sizes. Now this pocket is adjusted to the size of the cricket - since, according to statistics, this is the lighter that most people use.

As for this theory, Foto-elf magazine notes that it cannot be true since the first zippo lighter was released only in 1933, and the fifth pocket appeared on jeans back in 1873.

“How to choose high-quality jeans and not run into a fake?” - very simple. When choosing, you need to pay attention to the following aspects:

Textile.

The first thing you need to pay attention to is the texture of the fabric. The rule: “Jeans should be tight” was an undeniable truth as long as they ruled the roost. classic jeans. With the advent of jeggings and super-skinny models, you need to take into account that in such models the fabric is thinner by default.

Denim weaving can be done in several ways. The best and most common twill weave is diagonal ribs, directed from right to left and from top to bottom. Twill weaving can be present in both thicker and thinner fabrics. With twill weaving on the reverse side, the jeans are light and undyed. Jeans made from this fabric are highly wear-resistant and are not cheap.

If the herringbone weave of denim is a broken twill weave. These jeans are thinner and less textured than classic twill weave. Wear resistance is also quite high.

Another type of denim is jean fabric. Gin - cheap soft cotton fabric low quality, entirely painted in one color. Inexpensive jeans are made from gin.

Cheap summer jeans use a fabric called chambrie. This fabric feels very thin to the touch, without texture. Chambry weaving is very soft (1/1 - warp and weft threads are intertwined with each other one to one), has low wear resistance, and therefore is absolutely not suitable for sewing jeans.

Fabric structure

100% cotton for true jeans connoisseurs. Pros: naturalness, high wear resistance, hypoallergenic, easy to care for.

Stretch is a fabric with the addition of elastane. As a rule, 2-7% is added as a percentage. Most jeans are now made from stretch fabric; these jeans perfectly emphasize the silhouette, hug the figure tightly, have increased wear resistance, and stretch less at the knees.

Paint fastness

Any jeans fade during the first wash - this is normal phenomenon for indigo dyed items. But jeans will never stain your skin when worn.

Scuffs and holes are achieved different ways. In cheap jeans, white washes are achieved by applying acid to the fabric. This method is fast, cheap and often very harmful to health - cheap paint oxidizers often cause exacerbated allergic reactions, as well as unpleasant sensations on the skin. Visually, such “scuffs” are easy to distinguish - they look very bright, like a stain from spilled paint, the fibers in the clarified area are uniformly light.

In branded jeans, abrasions are achieved using a more labor-intensive and expensive method - mechanically. They go through such stages as: Stone wash, Enzyme wash, Brushing. Such abrasions look natural, the color is not so bright and uniform, and upon close examination, unevenness and precisely “abrasion” are visible on the fibers.

Label

The label for the manufacturer is as important as the final appearance of the finished product. As a rule, the label on branded jeans is made from genuine leather, neatly stitched and with a raised inscription. IN last years Manufacturers, in a burst of creativity, can also sew on a fabric label. But even in this case, the inscription will be raised, written neatly and in a proprietary font.

The internal sewn-in label with information about the manufacturer and care instructions should also be sewn very neatly, evenly, the information should be easy to read.

Accessories

If we talk about jeans, there can be no plastic here. Bolts, rivets, buttons in branded jeans are only metal (copper or bronze). This ensures their wear resistance. Bolts, buttons and zippers should have either a brand monogram or the abbreviation YKK. The zipper should be fastened neatly and have a double lock.

Quality of jeans cut

How can you easily check the quality of a cut? It is necessary to fold the jeans and see if the pant leg wrinkles or if the seams are distorted. If so, then such jeans will bring a lot of inconvenience when worn - a constantly twisted pant leg.

Seams– the pride of quality jeans. In classic jeans, the outer seams are made with contrasting thread, usually yellow or orange. The thread itself should be dense and strong. In dress jeans, the color of the thread is allowed to match the color of the fabric or another color. The main thing is that the seam should be smooth, without wrinkles or folds.

Internal seams should also be done carefully, the edges should be smooth without protruding threads. The width of the seam is absolutely even along the entire length.

Friends, enjoy your denim shopping, making the right choice and sunny mood!

Jeans are a familiar and familiar item of clothing. They are suitable for walks, parties and for work with a relaxed dress code. Surprisingly, ordinary work pants and overalls have turned into fashionable clothes, known all over the world. The famous blue jeans are far from the only thing that is made from this dense, reliable and versatile fabric.

Exist different kinds denim material. They differ somewhat and are the same in their manufacturing method, dyeing, thread weaving, characteristics and methods of application.

Who invented jeans?

The development of denim began, in fact, with the manufacture of jeans. In 1853, American entrepreneur Levi Strauss came up with the idea of using durable hemp canvas pants as farm work clothes. This material was very durable and cheap because the sailing fleet was in decline.

It so happened that all of Strauss's goods were sold out, and he only had canvas left. It was decided to make durable pants from it - they sold out instantly. For the next batch we used French denim fabric.

This is how the world's first classic jeans were created. Denim was a practical, very dense material, tough and rough. The fabric was difficult to tear and provided excellent protection for the wearer while working.

The studded pants sold out quickly

The studded pants sold out quickly The invention was patented. Levi Strauss & Co sold 21,000 copper-studded pants and jackets in its first year. The company also produced work overalls with many convenient pockets.

The heyday of jeans came during the gold rush. Searchers appreciated durable, durable items that were affordable and washable, unlike leather clothing.

Less than a hundred years later, cotton almost completely replaced hemp fabric. In the 1960s, the “denim revolution” occurred - new types and colors of fabric appeared, and the range of clothing expanded.

Jeans and denim: history and origin

Levi Strauss was the inventor of the garment. Thanks to him, denim became popular all over the world. However, this material was used long before the creation of the famous pants with rivets.

Cotton twill fabric

Cotton twill fabric Cotton twill fabric was known in Europe back in the 16th century. It was a variety of bumazea produced in Genoa. In Italy the material was called gene, in France – jane, in America – jean. At the end of the twentieth century, the word “jeans” appeared in the Russian language.

But what is denim? It's still the same denim fabric. The fact is that the material was produced in the French city of Nîmes. Denim is a fabric made from Nimes (de Nimes). But the deep blue indigo dye that the craftsmen used came from Genoa. Italian sailors wore "gines" as early as 1597 - it was a fabric for sails.

Manufacturing

Absolutely all types of denim contain cotton - natural fibers that are obtained from a plant called cotton plant. When the plant matures, it opens the seed capsule, which also contains soft, fluffy fibers. At the factory, the fibers are cleared of seeds and sorted by length.

To make denim, yarn with long, uniform fibers is used. Finished threads are obtained by twisting and are used for both warp and weft.

The best threads for denim are made on ring spinning machines, which twist the fibers well and tightly. A cheaper production method is the use of rotary pneumomechanical apparatus. The fibers are not twisted, but mixed up - such a thread is inferior in quality to a twisted one. Rotary machines work much faster than ring spinning machines, and less money is spent on the process. Manufacturers combine threads obtained in different ways - the quality of the fabric may vary.

To make durable denim fabric, twill weave is used - the fabric is obtained with a clear relief in a diagonal rib. Often the material is not completely dyed, but only the longitudinal, main threads. The weft (horizontal, transverse threads) that braids the warp is left untreated.

The material is dyed blue with indigo dye. Sulfur dyes are used to produce gray and black colors.

Types of fabric

A distinctive feature of denim is a special type of dyeing. Not all threads are dyed, but only the main, longitudinal ones. From the inside, the material looks much paler. Depending on the color and composition of the fabric, there are:

- denim - dense, coarse colored fabric, light on the inside;

- chambray (chambry) - light, soft material;

- broken line - fabric with herringbone weave, embossed and very dense;

- gin is a plain fabric with diagonal weaving of threads, economical and affordable;

- stretch or stretch - cotton with the addition of lycra, an elastic synthetic fiber;

- natural stretch - elastic fabric without added synthetics, consists of cotton and Chinese nettle ramie fibers;

- denim-silk - smooth material with a glossy sheen;

- ecru (eykru) is an undyed cotton fabric of a pale, gray-yellow color.

The quality of the material will largely depend on the origin of the cotton. There are the following types of raw materials:

- Mexican cotton - thanks to its long fibers, it produces a smooth, scar-free fabric;

- Barbados - soft, shiny cotton, expensive and rare on sale;

- Indian and Asian - the most common type of cotton, affordable and found everywhere.

Denim fabrics are also made from cellulose material. These jeans are softer and lighter, velvety, pleasant to the touch. Despite similar production technologies, Tencel is stronger than viscose, helps regulate heat transfer, and holds paint firmly. It is considered a worthy replacement for the classic one.

Characteristic

Cotton fabrics are famous for their strength and reliability. The material has conquered the whole world. A denim item can probably be found in any wardrobe. List of advantages of the material:

- wear resistance and versatility - in denim clothes you can walk for years, it is durable;

- hygroscopicity – absorbs moisture well;

- the fabric “breathes” - the fibers allow air to pass through well, but at the same time protect from the wind;

- does not electrify and does not allow dust to pass through;

- versatility - a large number of different things are sewn from denim (from accessories to wardrobe items);

- attractive appearance, convenience and comfort.

Flaws:

- after washing, the fabric shrinks and may become stiffer;

- dries slowly after washing;

- the material fades over time and rubs off where wrinkles most often form.

The disadvantages of the fabric are explained by its natural composition. Unfortunately, it is synthetic fibers that are more durable, while cotton wears out and loses positive properties from frequent use.

What is made from denim?

The material can be hard or light, colored or unpainted. This range of characteristics allows you to create a huge number of different items of clothing and accessories.

From dense fabrics they sew:

- jeans trousers, shorts, jackets, overalls, skirts, vests, corsets;

- bags, backpacks;

- shoes, boots;

- Panama hats and baseball caps.

From soft materials (chambray, for example) they make:

- blouses, shirts, tunics, sundresses;

- children's clothing (dresses, sundresses, overalls);

- swimwear;

- underwear.

Denim in the interior

Denim in the interior Denim fabrics are easy to decorate. Products are decorated with ribbons, lace, buckles, stripes, and rivets. The fabric does not fray, so deliberately torn jeans last as long as classic models. Products are painted in various colors, patterns and embroidery are made.

There are dozens of models of denim trousers alone - tapered, flared, straight, low- and high-waisted, torn and frayed, wide-legged at the hips, with or without cuffs, with pockets and completely smooth.

Subtleties of care

Despite its durability, denim fabrics are demanding and require proper care. For example, you should not take them to the dry cleaner - the item may shrink a lot after interacting with chemical cleaning agents. The basic rules are:

- denim items are washed separately from other fabrics;

- products are turned inside out and all accessories are covered (zippers, buttons, buttons);

- It is better to avoid bleach; stains and stains may remain;

- It is not recommended to wring out denim fabrics too much; it is best to let the water drain on its own;

- due to its rigidity, denim retains its shape well and items almost do not need to be ironed - they straighten out on the body;

- If such a need arises, iron the products slightly damp - they will become softer.

Compliance with simple requirements will allow you to preserve your denim items for as long as possible. A pair of navy cotton twill trousers is already considered a classic. In combination with shirts and blouses, jeans look presentable and highlight the lines of the figure.

Denim fabrics go well with other materials, accessories, and decor. They create both everyday and elegant, festive items. The long history of denim and its varieties allows us to draw the following conclusion: denim fabrics are comfort and durability, proven over centuries.

Making denim, video: